OPTIMIZATION OF PROCESS PARAMETERS OF WIRE-CUT ELECTRIC DISCHARGE MACHINE Mr. Harish Kumar Sharmaa , Mr. Deepak Guptaa Abstract-...

OPTIMIZATION OF PROCESS PARAMETERS OF WIRE-CUT ELECTRIC DISCHARGE MACHINE

Mr. Harish Kumar Sharmaa , Mr. Deepak Guptaa

Abstract-Wire-cut Electric Discharge Machine (WEDM) process is one of the most widely used non-traditional

machining processes in current manufacturing. It involves the removal of metal by discharging an electrical current from

a pulsating DC power supply across a thin inter-electrode gap between the tool and the work piece. It is most

commonly used for machining hard and difficult to machine materials with very close tolerances. This work presents an

investigation on effect and optimization of machining parameters for cutting speed, die width. Surface roughness, in

wire electric discharge machining. Tungsten die tool steel is used for this research. It is commonly used for hot

working dies and tooling such as die casting, extrusion and hot forming of parts. It has been observed that effect of

each process parameter for optimization of each performance measure is different. MINITAB 15 software is also used

to find the effect of each parameter on response characteristic and to predict the setting of control parameters.

GJRE: Global Journals Blog

GJRE: Global Journals Blog

I. INTRODUCTION

Wire electrical discharge machining or WEDM is a metal working process, with the help of which a material is

separated from a conductive work piece, by the process called electrical erosion. The wire is not in touch with the

conductive work piece. The wire electrode generates a path on the work piece, which is slightly larger than the wire.

Mostly a 0.010 inch (0.25 mm) wire is used which made a 0.013 to 0.014 inch gap. The wire electrode once passed

through and cannot be reused.

The wire electrode and the work piece are held at an accurately controlled distance from one another, which are dependent on the operating condition and refer to as spark gap. This gap prevents the mechanical contact of tool and work. The movement of wire is controlled numerically using computer to achieve the dimensional shape and accuracy of the desired value.

The wire electrode and the work piece are held at an accurately controlled distance from one another, which are dependent on the operating condition and refer to as spark gap. This gap prevents the mechanical contact of tool and work. The movement of wire is controlled numerically using computer to achieve the dimensional shape and accuracy of the desired value.

II. PRINCIPLE OF WEDM

WEDM puts impulse voltage between the electrode wire and work piece through impulse source, controlled by using servo system, to get a certain desired gap, and realize impulse discharging in the working liquid between electrode wire & work-piece. Numerous tiny small holes appear due to erosion of impulse discharging and therefore get the required shape of work-piece (as shown in figure 1.1) Electrode wire is connected to the cathode of impulse power source, and work piece is connected to the anode of impulse power source. When the work piece is approaching insulating liquid and gap between them getting small to a certain value, insulating liquid was broken through; very shortly, discharging channel are formed, and electrical discharging happen. This result in high temperature instantaneously, temperature reaches up to above 10000 degree centigrade, the eroded work piece is cooled down swiftly in working liquid and flushed away. Wire electrode is generally made up of copper, brass or tungsten of diameter 0.05mm to 0.3mm, which is capable to achieve a very small corner radii. When the equipoise voltage is applied across the two electrode separated by a dielectric fluid, the latter starts breaking down. The electrons, so liberated are accelerated in presence of the electric field and starts colliding with the dielectric molecules, causing the latter to be robbed off their electrons.

III. EXPERIMENTAL PROCEDURE

Experiments were conducted to study the effects of the various machining parameters on WEDM working. Studies have been undertaken to investigate the effects of the important parameters viz., Discharge current, pulse on time, pulse off time, wire speed and wire tension on cutting speed, surface roughness and die width.

Work piece Electrode

The work piece material is used in this investigation was H21 die tool steel. Composition of H21 die tool steel is C= 0.30%, Mn= 0.30% , Si=0.20% ,Cr= 3.60%, Ni=0.3%, W= 8.5%, V= 0.40%,Cu=0.25,P=0.03 and S=0.03. A H21 die tool steel plate of size 200x50x20 (l x b x w) could reach the HB300 at the temperature of 650 C

Work piece Electrode

The work piece material is used in this investigation was H21 die tool steel. Composition of H21 die tool steel is C= 0.30%, Mn= 0.30% , Si=0.20% ,Cr= 3.60%, Ni=0.3%, W= 8.5%, V= 0.40%,Cu=0.25,P=0.03 and S=0.03. A H21 die tool steel plate of size 200x50x20 (l x b x w) could reach the HB300 at the temperature of 650 C

All the six faces of tool steel plate are grinded to remove the burrs and rusts so that wire moves smoothly throughout the work piece. H-21 die tool steel is also characterized by its high dimensional stability after hardening and tempering, high compressive strength. The success of a metal forming tool is depending on optimizing all the factors which is affecting its performance. Usually, operating conditions (applied loads, abrasive environments, impacts, and other factors) determine how well a tool holds up. Most of the tool failures are related to such mechanical causes. Table shows the physical properties of H21 die tool steel.

IV. SCHEME OF EXPERIMENTS

Taguchi parametric design methodology was adopted in this experiment. The experiments were conducted by using the Taguchi’s L18 OA array.

Five controllable factors were selected.Parameters of the setting are given in

Five controllable factors were selected.Parameters of the setting are given in

V. SELECTION OF ORTHOGONAL ARRAY (OA) AND PARAMETER ASSIGNMENT

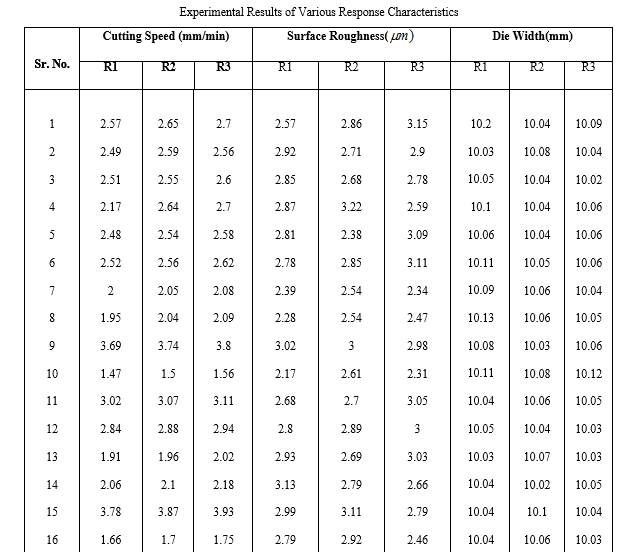

In this phase, five process parameters viz. peak current, pulse on time; pulse off time, wire speed and wire tension were selected as given in Experiments were conducted according to the test conditions specified by the L18 OA In each of the trial conditions cutting speed, die width and surface roughness were measured. The data recorded

V. RESULT AND DISCUSSION

In this chapter we will be analyzed the result of experiment presented

Analysis of Result for Single Response Optimization

The experiment was carried out by using the approach of the Taguchi’s method. The response characteristics data of the group are provided. The standard procedure to be analyze the data, as suggested by Taguchi, is employed. The average value, mean data and S/N ratio of the quality response characteristics for cutting speed, die with and surface roughness at different level are calculated from experimental data. The main effects of the process parameter for raw data and S/N data are shown in the graph. These are used for examining the parametric effect on the response characteristics. The analysis of variance (ANOVA) for the raw data and S/N ratio is performed to identify the significant parameters and to quantify their effect on the response characteristics. The most optimal setting of the process parameters in terms of mean response characteristics is established by analyzing the response curve and the ANOVA tables

We used the software “MINITAB 15” to analyze the response data specially used for the design of experiment application.

In this section we discussed the effect of WEDM process parameters( peak current, pulse on time, pulse off time, current, wire speed and wire tension) on the response characteristics(cutting speed, die width and surface roughness). The average value of response characteristics, mean data and S/N ratio for each parameter at all levels are

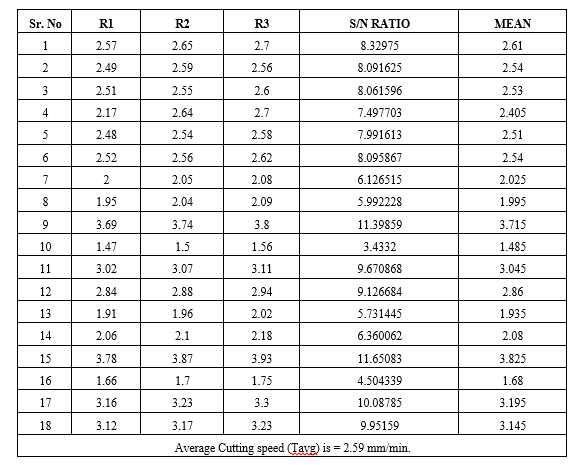

Effect of Parameters on Cutting Speed (CS) The average value of the cutting speed and the S/N ratio for each parameter at different level are calculated using MINITAB 15 and given. The response tables for mean and S/N ratio are given in These values are shown in

Analysis of Result for Single Response Optimization

The experiment was carried out by using the approach of the Taguchi’s method. The response characteristics data of the group are provided. The standard procedure to be analyze the data, as suggested by Taguchi, is employed. The average value, mean data and S/N ratio of the quality response characteristics for cutting speed, die with and surface roughness at different level are calculated from experimental data. The main effects of the process parameter for raw data and S/N data are shown in the graph. These are used for examining the parametric effect on the response characteristics. The analysis of variance (ANOVA) for the raw data and S/N ratio is performed to identify the significant parameters and to quantify their effect on the response characteristics. The most optimal setting of the process parameters in terms of mean response characteristics is established by analyzing the response curve and the ANOVA tables

We used the software “MINITAB 15” to analyze the response data specially used for the design of experiment application.

In this section we discussed the effect of WEDM process parameters( peak current, pulse on time, pulse off time, current, wire speed and wire tension) on the response characteristics(cutting speed, die width and surface roughness). The average value of response characteristics, mean data and S/N ratio for each parameter at all levels are

Effect of Parameters on Cutting Speed (CS) The average value of the cutting speed and the S/N ratio for each parameter at different level are calculated using MINITAB 15 and given. The response tables for mean and S/N ratio are given in These values are shown in

Average value of the Cutting speed, calculated from raw data is 2.59mm/min. it is clear from the S/N plots the maximum S/N ratio occur corresponding A6, B3, C1, D1 and E3. Therefore the optimum value will be corresponds to these factor but the only significant factor would be chosen. This factor will be chosen from the ANOVA table.

VI. SELECTION OF OPTIMUM LEVEL

In order to study the significance of the process parameter toward the cutting speed, ANOVA is performed. The ANOVA of the raw data and S/N data are given in MINITAB 15 is used for ANOVA

For 95% of confidence level value should be less than 0.05. Therefore, from the above table , it is clear that the only four parameters A, B, C, D significantly affect the mean and variation in the value of cutting speed. Cutting speed is the “higher is better” type of characteristics. Therefore higher value of cutting speed is considered to be optimal.

Optimal value of cutting speed = (A6+B3+C1+D1) – 3 (Tavg) = 3.71mm/min

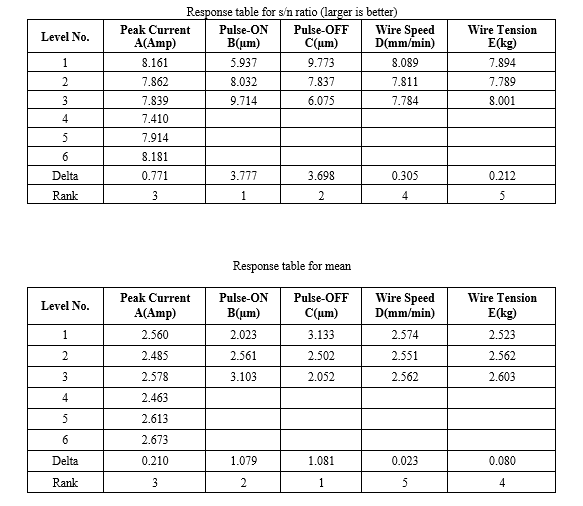

Effect of Parameters on Die Width

For better performance of the die it should be dimensionally accurate so that it matches with the punch. In this study die width of parallel side is measured

Dimensional accuracy is a “nominal is best” type characteristic. Table no 5.6 gives the details of the raw data and S/N data of die width. Main effect of each parameter is calculated from response table 5.7 and 5.8 shown in figure 5.2. These effect are plotted using MINITAB 15

Effect of Parameters on Die Width

For better performance of the die it should be dimensionally accurate so that it matches with the punch. In this study die width of parallel side is measured

Dimensional accuracy is a “nominal is best” type characteristic. Table no 5.6 gives the details of the raw data and S/N data of die width. Main effect of each parameter is calculated from response table 5.7 and 5.8 shown in figure 5.2. These effect are plotted using MINITAB 15

Average value of the die width, calculated from the raw data is 10.06. It is clear from the and response the maximum S/N ratio occurs corresponds to A4, B3, C2, D3, E3. Therefore the optimum value will be the corresponds to these factor but the only significant factor will be chosen. The significant factors are chosen from ANOVA table.

Selection of Optimum Level In order to find out the significant process parameters level which affect the die width, ANOVA is performed. The ANOVA of the raw data is obtained with the help of MINITAB 15 and is given

Selection of Optimum Level In order to find out the significant process parameters level which affect the die width, ANOVA is performed. The ANOVA of the raw data is obtained with the help of MINITAB 15 and is given

From the ANOVA table, it should be noticed that four parameter A, B and C and D significantly affect both the mean and variation in the value of die width. Die width is the “nominal the better “type of characteristics. Predicted optimal value of surface roughness is = 10.06 mm (A4+B3+C2+D3) –3(Tavg)

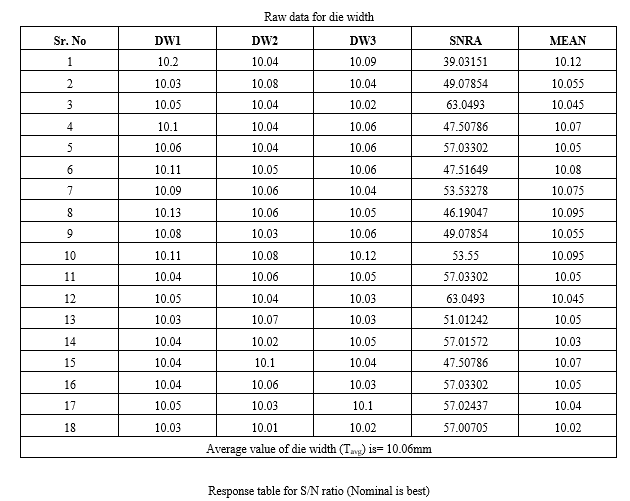

Effect of Parameters on Surface Roughness

The Raw data and S/N data for the surface roughness is given in table5.11. Surface roughness is a key factor in die making and depends upon the energy drop across the electrodes. Surface roughness is a “smaller is better” type characteristics so optimum value of surface roughness should be low so that depth of recast layer remains minimum or equal to zero.

Average value of surface roughness is 2.81. Main effects of each parameter are calculated from response and shown These effects are plotted using MINITAB 15

It is clear from the S/N plots the maximum S/N ratio occurs correspond to A3, B1, C3, and D1and E3. Therefore the predicted mean value will be corresponding to these factor but the only significant factors would be chosen. The significant factors are chosen from ANOVA table.

5.4.1 Selection of the optimum level

In order to study the significance of process parameters toward the Surface Roughness, analysis of variance (ANOVA) is performed. The ANOVA of the raw data and S/N data are given in table 5.14 and 5.15.

In order to study the significance of process parameters toward the Surface Roughness, analysis of variance (ANOVA) is performed. The ANOVA of the raw data and S/N data are given in table 5.14 and 5.15.

It is clear from the ANOVA table that no single parameter (value close to P = 0.05) significantly affect both mean and variation in the case of surface roughness so we have to consider all factors. Surface roughness is the “smaller the better” type of quality characteristics. Therefore lower value of the surface roughness is considered to be optimal. Predicted optimal value of surface finish is = 2.32µm (A3+B1+C3+D1+E3)- 4(Tavg)

VII. CONCLUSIONS AND SCOPE FOR FUTURE WORK

- The average cutting speed is mostly affected by the pulse-on, pulse-off, peak current and wire feed during rough cut.

- There is no most significant factor that affects the Surface Roughness as the value of P in ANOVA table comes greater than 0.1. But the ranking of influence of five parameters that is used in this investigation are: A=1, B=3, C=2,D=5, E=4

- The die width is mostly affected by the peak current, pulse-on, pulse-off and wire feed rate during rough cut.

- Confirmation experiment shows that error(%) is associated with cutting speed, die width and surface finish is 2.96, 0.1, 4.16

Scope for Future Work

- L18 orthogonal array does not provide interaction between the different parameters.Therefore higher order orthogonal array (OA) like L27 can be considered to incorporate all the possible interactions of the process parameters.

REFERENCES RÈFÈRENCES REFERENCIAS

1. A.Thillaivanan , P. Asokan, K. N. Srinivasan, R.Saravanan (2010) “Optimization of operating parameters for EDM process based on the Taguchi method and artificial neural network” Vol.2(12),6880-6888,

2. Adam Cicek,Turgay Kivak,Gurcan Samtas (2012) “Application of Taguchi Method for Surface Roughness and Roundness Error in Drilling of AISI 316 Stainless Steel” Vol 58, Page No. 165-174

3. Anish Kumar, Vinod Kumar, Jatinder Kumar (2012) “Prediction of Surface Roughness in Wire Electric Discharge Machining (WEDM) Process based on Response Surface Methodology” Vol 2, No.4

4. Aniza Alias, Bulan Abdullah, Norliana Mohd Abbas (2012) “WEDM: influence of machine feed rate in machining titanium ti-6al-4v using brass wire and constant current (4a)” Vol No 41, Page No.1812-1817

5. Aniza Alias, Bulan Abdullah, Norliana Mohd Abbas (2012) “Influence of machine feed rate in WEDM of titanium ti-6al-4v with constant current (6a) using brass wire” Vol No 41, Page No.1806-1811

6. B.T.H.T Baharudin, M.R. Ibrahim, N Ismail, Z. Leman, M.K.A. Ariffin, D.L.Majid(2012) “Experimental Investigation of HSS Face Milling to AL6061 using Taguchi Method” Vol No 50, Page No.933-941

7. Fuzhu Han, Jun Jiang, Dingwen (2007) “Influence of machining parameters on surface roughness in finish cut of WEDM”Vol No 34, Page No.538-546

8. H.Singh, R. Garg (2009) “Effects of process parameters on material removal rate in WEDM”Vol 32, Page No.70-74

9. Jaganathan P , Naveen Kumar, Dr. R.Sivasubramanian (2012) “Machining Parameters Optimization of WEDM Process Using Taguchi Method” Vol 2, Page No 1-4

10. Kevin N. Otto , Erik. K. Antonsson (1991)“Extensions to the Taguchi Method of Product Design”.

11. Mohd Amri Lajis, H.C.D. Mohd Radzi, A.K.M Nurul Amin (2009) “The Implementation of Taguchi Method on EDM Process of Tungsten Carbide”Vol.26 No.4 , pp.609-617

12. Muthu kumar V, Suresh babu A, Venkatesamy R and Raajenthiren (2010) “ Optimization of the WEDM Parameters on Machining Incoloy800 Super alloy with Multiple Quality Characteristics”Vol. 2(6),1538-1547

13. Muthu kumar V, Suresh Babu A, Venkatasamy R, Raajenthiren M (2010)“Parametric optimization of wire-cut EDM process using grey based Taguchi method for machining titanium alloy (TI-6AL-4V)”Vol. 2, No. II, pp. 77-92

14. Muthuraman V, Ramakrishnan.R, Puviyarasan M (2012) “Interactions of process parameters during WEDM of WC-Co composite”

15. Pichai Janmanee et al (2011) “Optimization of Electrical Discharge Machining of Composite 90WC-10Co Base on Taguchi Approach.”Vol.64 No.3, pp. 426-436

16. Pujari Srinivasa Rao, Koona Ramji (2011) “Effect of WEDM conditions on surface roughness: a parametric optimisation using Taguchi method” Vol No. 6, pp- 041-048

17. Resit Unal, EdwinB. Dean “taguchi approach to design optimization for quality and cost:an overview

18. R.N Ahmad, M.N.Derman, M.Marzuki (2010) “Primary study on machinability of aluminium matrix composite using WEDM”Vol: 10 No: 06, pp 145-150

19. R.Ramanujam,R.Raju,N.Muthukrishnan (2010) “Taguchi Multi-machining Characteristics Optimization in Turning of Al-15%SiCp Composites using Desirability Function Analysis”Vol.1 pp. 120-125

20. Ross, Philip J., Taguchi Techniques for Quality Engineering, McGraw Hill Book Company, New York, 1996.

21. S.Boopathi, K Sivakumar, (2012)“Experimental Comparative Study of Near-Dry Wire-Cut Electrical Discharge Machining (WEDM)” Vol. 75 No.4, pp. 472-481.

22. S.Boopathi, K Sivakumar,R.Kalidas (2012) “Parametric Study of Dry WEDM Using Taguchi Method” Vol. 2, pp. 63-68

23. S.K.Sinha (2010) “Effects of wire lag in wire electrical discharge machining (WEDM)”Vol. 2(11), 2010, 6622-6625.

24. S.S.Mahapatra and Amar Patnaik (2006) “Optimization of wire electrical discharge machining (WEDM) process parameters using genetic algorithm” Vol. 13, pp. 494-502

25. S.S.Mahapatra, Amar Patnaik (2006) “Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method”

Published by Global Journals

© Global Journals Official Blog 2016

2. Adam Cicek,Turgay Kivak,Gurcan Samtas (2012) “Application of Taguchi Method for Surface Roughness and Roundness Error in Drilling of AISI 316 Stainless Steel” Vol 58, Page No. 165-174

3. Anish Kumar, Vinod Kumar, Jatinder Kumar (2012) “Prediction of Surface Roughness in Wire Electric Discharge Machining (WEDM) Process based on Response Surface Methodology” Vol 2, No.4

4. Aniza Alias, Bulan Abdullah, Norliana Mohd Abbas (2012) “WEDM: influence of machine feed rate in machining titanium ti-6al-4v using brass wire and constant current (4a)” Vol No 41, Page No.1812-1817

5. Aniza Alias, Bulan Abdullah, Norliana Mohd Abbas (2012) “Influence of machine feed rate in WEDM of titanium ti-6al-4v with constant current (6a) using brass wire” Vol No 41, Page No.1806-1811

6. B.T.H.T Baharudin, M.R. Ibrahim, N Ismail, Z. Leman, M.K.A. Ariffin, D.L.Majid(2012) “Experimental Investigation of HSS Face Milling to AL6061 using Taguchi Method” Vol No 50, Page No.933-941

7. Fuzhu Han, Jun Jiang, Dingwen (2007) “Influence of machining parameters on surface roughness in finish cut of WEDM”Vol No 34, Page No.538-546

8. H.Singh, R. Garg (2009) “Effects of process parameters on material removal rate in WEDM”Vol 32, Page No.70-74

9. Jaganathan P , Naveen Kumar, Dr. R.Sivasubramanian (2012) “Machining Parameters Optimization of WEDM Process Using Taguchi Method” Vol 2, Page No 1-4

10. Kevin N. Otto , Erik. K. Antonsson (1991)“Extensions to the Taguchi Method of Product Design”.

11. Mohd Amri Lajis, H.C.D. Mohd Radzi, A.K.M Nurul Amin (2009) “The Implementation of Taguchi Method on EDM Process of Tungsten Carbide”Vol.26 No.4 , pp.609-617

12. Muthu kumar V, Suresh babu A, Venkatesamy R and Raajenthiren (2010) “ Optimization of the WEDM Parameters on Machining Incoloy800 Super alloy with Multiple Quality Characteristics”Vol. 2(6),1538-1547

13. Muthu kumar V, Suresh Babu A, Venkatasamy R, Raajenthiren M (2010)“Parametric optimization of wire-cut EDM process using grey based Taguchi method for machining titanium alloy (TI-6AL-4V)”Vol. 2, No. II, pp. 77-92

14. Muthuraman V, Ramakrishnan.R, Puviyarasan M (2012) “Interactions of process parameters during WEDM of WC-Co composite”

15. Pichai Janmanee et al (2011) “Optimization of Electrical Discharge Machining of Composite 90WC-10Co Base on Taguchi Approach.”Vol.64 No.3, pp. 426-436

16. Pujari Srinivasa Rao, Koona Ramji (2011) “Effect of WEDM conditions on surface roughness: a parametric optimisation using Taguchi method” Vol No. 6, pp- 041-048

17. Resit Unal, EdwinB. Dean “taguchi approach to design optimization for quality and cost:an overview

18. R.N Ahmad, M.N.Derman, M.Marzuki (2010) “Primary study on machinability of aluminium matrix composite using WEDM”Vol: 10 No: 06, pp 145-150

19. R.Ramanujam,R.Raju,N.Muthukrishnan (2010) “Taguchi Multi-machining Characteristics Optimization in Turning of Al-15%SiCp Composites using Desirability Function Analysis”Vol.1 pp. 120-125

20. Ross, Philip J., Taguchi Techniques for Quality Engineering, McGraw Hill Book Company, New York, 1996.

21. S.Boopathi, K Sivakumar, (2012)“Experimental Comparative Study of Near-Dry Wire-Cut Electrical Discharge Machining (WEDM)” Vol. 75 No.4, pp. 472-481.

22. S.Boopathi, K Sivakumar,R.Kalidas (2012) “Parametric Study of Dry WEDM Using Taguchi Method” Vol. 2, pp. 63-68

23. S.K.Sinha (2010) “Effects of wire lag in wire electrical discharge machining (WEDM)”Vol. 2(11), 2010, 6622-6625.

24. S.S.Mahapatra and Amar Patnaik (2006) “Optimization of wire electrical discharge machining (WEDM) process parameters using genetic algorithm” Vol. 13, pp. 494-502

25. S.S.Mahapatra, Amar Patnaik (2006) “Optimization of wire electrical discharge machining (WEDM) process parameters using Taguchi method”

Published by Global Journals

© Global Journals Official Blog 2016